Excessive inflow and infiltration (I&I) can cause a collections system to exceed its capacity limits, leading to increased treatment costs and sanitary sewer overflows that release untreated effluent into the environment. And aggressive cleaning programs, while effective at clearing pipes of debris, result in some pipes getting over-cleaned. This wastes resources and leads to premature pipe degradation and, eventually, early pipe failure.

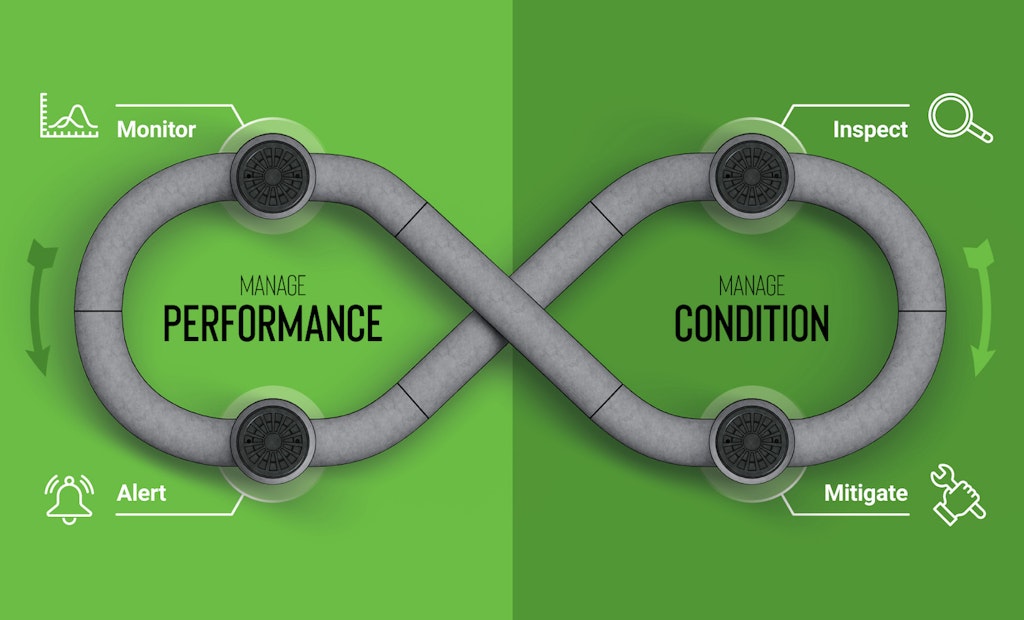

A new workflow takes both sewer performance and sewer condition management into account, enabling subcontractors to help municipalities stay ahead of collections system maintenance — under budget.

Step 1: Monitor

There’s an easy way to stay on top of collections system’s performance: remote site monitors. These next-generation ultrasonic systems are mounted at the top of the manhole and provide continuous measurements of levels. They can detect both low flow conditions, indicating an upstream issue, or high flow conditions, suggesting a downstream issue. The monitors provide operators with continuous, real-time data and alarms. Remote site data is sent to cloud-based software where operators have viewing access and can take advantage of advanced capabilities including predictive analytics.

Step 2: Alert

Cloud-based software provides continuous user access, allowing operators to keep their eye on flow levels and hot spots 24/7 — and notifying them of concerns. When the predictive software observes a blockage forming, it sends an alert to the system’s main dashboard. These alerts are categorized for severity and prioritized for urgency. For extremely fast occurring events, alarms are sent via email or text message. However, most blockage formation is progressive in nature, which is where predictive software comes in.

Step 3: Inspect

Once alerted to a potential problem, an inspection is in order. CCTV crawlers are recognized as the best tools for collecting the most detailed data on sewer conditions. But it’s often more efficient to begin assessments by utilizing cost-effective, rapid inspection equipment like zoom survey cameras. Today’s HD zoom cameras are the perfect first line of defense for sewer inspectors, and offer an efficient, straightforward way to get a sense of pipe condition. When deployed in manholes, these powerful tools can see hundreds of feet into lines instantly.

After utilizing a zoom camera for initial inspection, hot spots that are in dire need of attention can get the detailed assessments they need with a CCTV crawler. With HD pan/tilt/zoom cameras, robust reporting capabilities, and add-on functions like laser and side-scan crawlers produce valuable footage that allows inspectors to flag defects and problem areas in need of repair or maintenance.

Step 4: Mitigate

Once pipe condition is thoroughly understood, digital workflows can automatically assign rehab and cleaning crews to address the issues. This maintenance can include cleaning, CIPP lining, point repair, traditional dig-and-replace work, and more — whatever maintenance is necessary to restore normal flow levels and ensure pipe integrity. And because crews know exactly where to go and what to target, there are no wasted efforts.

Once the situation has been mitigated, flow metering will continue the cycle of continuous monitoring.

Inspect smarter, not harder

Prioritizing the management of both sewer performance and sewer condition benefits the health and safety of ourselves, our communities and our natural environment. This workflow lays out the most efficient and cost-effective solution for complete sewer life cycle management.

Ready to dig deeper into sewer inspection workflows? The Phased Assessment Strategy for Sewers simplifies assessments and reduces costs. Get the free guide to PASS only from Envirosight:

Visit the Envirosight Storefront